- Dongguan regular ultra-silent terminal machine

- Zhanjiang automatic terminal machine company

- Common sense of the classification of the terminal machine stripping tape hitting terminal machine-Dongguan Kui Lun Machinery Co.

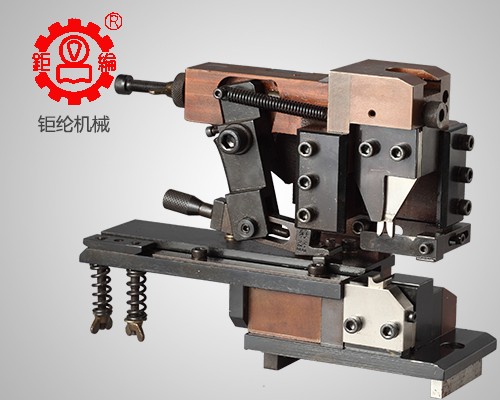

- Strip tape hitting terminal machine

- Super silent terminal machine introduction

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Zhanjiang automatic terminal machine company

Fully automatic terminal machine is a more convenient machine, we should also know this, fully automatic mechanical equipment Those with greater help can save a lot of labor and increase the output of the factory. It can also help the factory to temporarily relieve the problem of not being able to find workers. However, we are also using the fully automatic terminal machine when we use it. There will be a problem. Some time-division automatic terminal machines will have relatively loud noises after being used for a period of time. We should all be aware of this!

Zhanjiang Automatic Terminal Machine Company

Excessive pressure on the stripping terminal machine or other problems, check and debug to OK. Before operation, check each locking screw and confirm that there is no looseness inside. When the blade of the automatic terminal machine has undergone 200,000 times of stamping, there will be a certain degree of wear. At this time, the riveted terminal may have defective products. The cutting blade of the equipment has experienced 1 million or even 2 million times. After the cutting and stripping, there will be certain hidden dangers. Therefore, in the use process of high-demand customers, it is necessary to strictly control the service life of the wearing parts, and the correct operation of the equipment can also reduce the loss.

The length of the wire cut is inconsistent. A: The wire feed wheel is pressed too tightly or too loosely. Countermeasure: Adjust the straightening machine so that it can be straightened and sent out smoothly. There are two differences between professional production of terminal machines and automatic terminal machines. The first is the characteristics of the automatic terminal machine: the automatic terminal machine is an automatic machine that integrates wire feeding, wire cutting, stripping, terminal punching and other chemical machinery. The automatic terminal machine was developed and manufactured in Japan as early as, the operator only needs to touch the screen button to send information to the server, and then to the motor. The fully automatic terminal machine can complete all actions such as wire feeding, wire cutting, stripping, and terminal tapping within one second. Where to buy the safety of the terminal machine: talk about the functional advantages of where to buy the automatic terminal machine. The functional advantages of where to buy the automatic terminal machine are introduced as follows: Where to buy the automatic terminal machine refers to the kind of wire processing used The machine, also known as the fully automatic stripping and pressing machine, is a new type of equipment that has just been released in recent years. It is a multifunctional machine integrating feeding, cutting, stripping and pressing. It is a humanized and intelligent high-end technology product. Suitable for large, medium and small enterprises, saving labor. Increase work efficiency.

Adjustment of the closing height (crimping height) of Dongguan Julon automatic terminal machine: when the closing height of the stripping terminal machine is not suitable or the mold crimping height is adjusted by the micro adjuster plate When the amount is not enough, it can be achieved by adjusting the adjustment joint and loosening the round nut. Insert the adjusting rod into the round hole on the adjusting joint and turn it. Turning left will decrease the pressing height, and turning right will increase the pressing height (the engraved line on the adjusting joint is 0.1mm per grid, and one turn is 3mm). From high to low, adjust to the proper compression of the wires and terminals. It should not be too tight. Too tight will easily damage the upper and lower die blades. Tighten the round nut after adjustment.

As a humanized and intelligent high-end technology product, the automatic terminal machine is suitable for large, medium and small enterprises that need to use wire harnesses. It can save a lot of labor and is efficient Several times the semi-automatic terminal machine.

Stripping and tapping machineTurn the operation switch to the adjustment position (POWEROFF) and the motor will not run at this time. Insert the open-end wrench into the spindle from the rear box door, and press the manual button ○2 (ADJUST) solenoid to attract it. The open-end wrench rotates clockwise to drive the main shaft of the stripper and terminal machine to rotate one circle, the main slider of the stripper and terminal machine moves up and down to complete a stroke, and one terminal is crimped. The manual button, kept pressed, can be turned into place continuously, and then remove the open-end wrench. To proceed.

Zhanjiang Automatic Terminal Machine Company

Generally, it is normal to have fine noise. If it is a loud one, then there are these two problems, a. There is abrasion between certain parts and components of the terminal machine, which leads to increased conflicts; b. The screw of the terminal machine is loose during work, causing the parts to vibrate and become rugged.

Turn the adjustment rod to adjust until it is in a better condition, then tighten the feeder lock screw and start the operation. 5. Test the tension: After the adjustment is OK, take the scrap wire and test the tension test, press the tension test reset button to adjust to zero, the stripping terminal machine clamps the terminal wire to be tested, and conducts the test. The measured tensile force is not within the specification range, please adjust it from the beginning until it reaches the specification value and stop. 6. The trial production of 10PCS will be sent to IPQC for the first piece approval, and the inspection is OK before mass production can be carried out. During the production process, the operator must self-check whether the terminals have encapsulation, hanging necks, etc. defects, and do it every 1 hour A terminal pull test. 7. After the production is completed, the good and defective products should be sorted out, and the environment around the clean machine should be sorted out.

Zhanjiang Automatic Terminal Machine Company

The working principle of the semi-automatic terminal machine, the diagram is to put the qualified terminals on the terminal frame according to the requirements, and install the terminal chain head into the equipment according to the correct method. Recognize the equipment knife mold Match with the installed terminal, then adjust the pressure and other parameters of the pressure monitoring, and adjust the corresponding position of the terminal chain and the device. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and the terminal opening, adjust the position, and then step on the foot pedal with your foot to put the terminal on the wire.

Poor peeling of the stripper and terminal machine: the peeling time varies. There are many reasons for different stripping lengths. The common stripping length is too tight or too loose. At this time, it is only necessary to properly adjust the open space between the two wheels until the wire cannot be pulled by hand. On the other hand, this may be a problem with the blade. The blade is cut too deep or too shallow, and even the blade is installed at an angle, which may also cause this result. At this time, it is necessary to adjust the position of the blades as needed. If it is caused by damage to the blade, it is recommended to replace the blade immediately. Inconsistent cutting lengths Inconsistent cutting lengths may be due to blade or blade wear; to encounter such a problem, simply replace the cutter with a new one.

Zhanjiang Automatic Terminal Machine Company

The possible cause is that the wire feed wheel is too tight or too loose. At this time, we can fine-tune the gap between the two wheels with a steel wire roller, so that the steel wire will not become flat and too loose. The principle is roughly similar to the peel length. 2. Malfunction of the stripping terminal machine: Poor crimping terminals may lead to complete crimping, or not reaching a better crimping position, resulting in bare copper wires. At this time, it is necessary to check whether the gun-type swing arm catheter is installed on the wire. Whether the terminal blade of the swing arm catheter is relatively straight; whether the auxiliary pressing block of the terminal is loose; check whether the interval between the terminal and the automatic machine has been changed.

Zhanjiang Automatic Terminal Machine Company

Full-automatic parallel wire terminal machine. (It adopts PLC or single-chip control, servo motor or stepper motor to provide power. The production process does not require manual participation, and the production efficiency is high. This type of domestic equipment can realize about 7000pcs of wire cutting per hour and 11000pcs of terminal crimping. The mid-term is 3500pcs. Parallel wire crimping terminal, 7500pcs is a single wire crimping terminal, which can automatically detect the crimping quality of the terminal. It has the functions of the above three automatic terminal machines. It is currently one of the best automated terminal machines in the domestic market.)

-

2021-07-23 17:10:31Wuhu automatic terminal machine factory

-

2021-07-24 15:27:22Jining stock intelligent terminal machine

-

2021-07-24 14:29:50Shenzhen multiplayer exhibition fl

-

2021-07-24 14:50:33Terminal machine

-

2021-07-24 15:54:45Luoyang supply automatic terminal machine

-

2021-07-24 14:21:33Zaozhuang where to buy automatic terminal machine

-

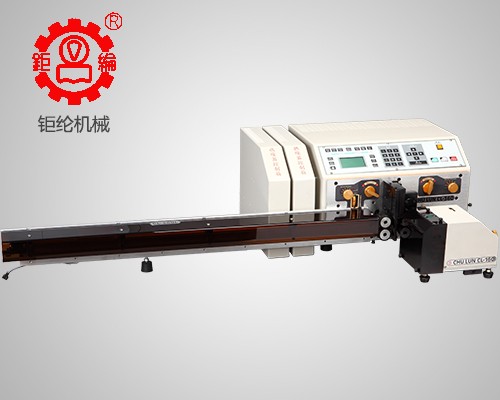

CL-RSB Automatic Terminal Crimping Machine (single head thick wire)

-

WRS-04+05 Shaft loading type wire release machine + wire feeder

-

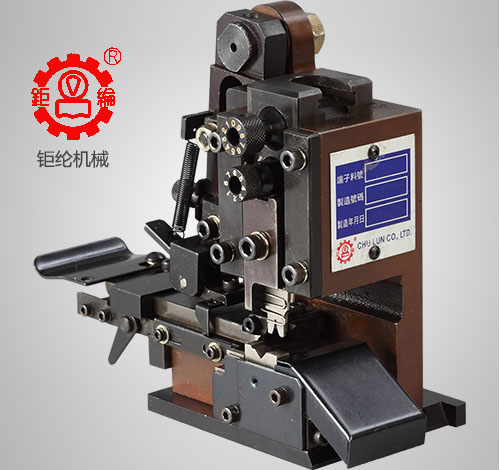

C1-3.0A Terminal Machine

-

CL-CWSS Single Head Short Wire Solder Dip Machine

-

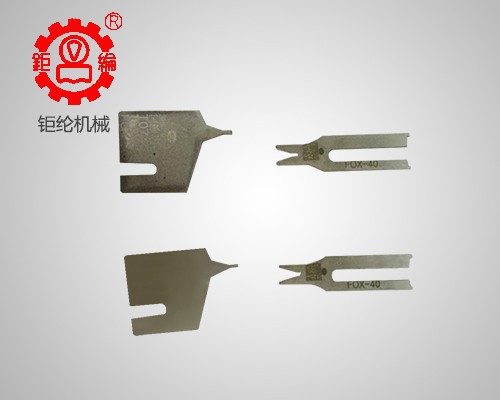

Special crimping knife

-

CN peeling knife

-

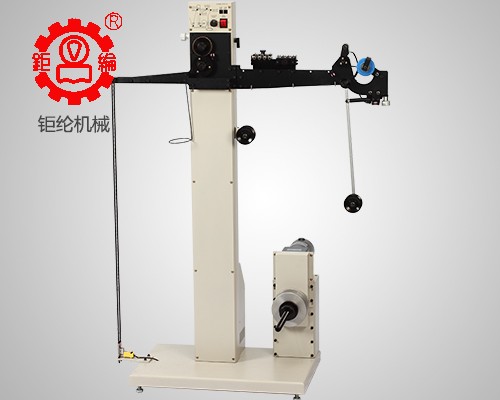

WRS-02 Multifunctional Wire Feeding Machine

-

CLM-2S card module

EN

EN

CN

CN

QQ customer service

QQ customer service